Energy Other

Covestro, Rondo Energy Break Ground on Heat Battery Project to Replace Fossil-Fuel Steam

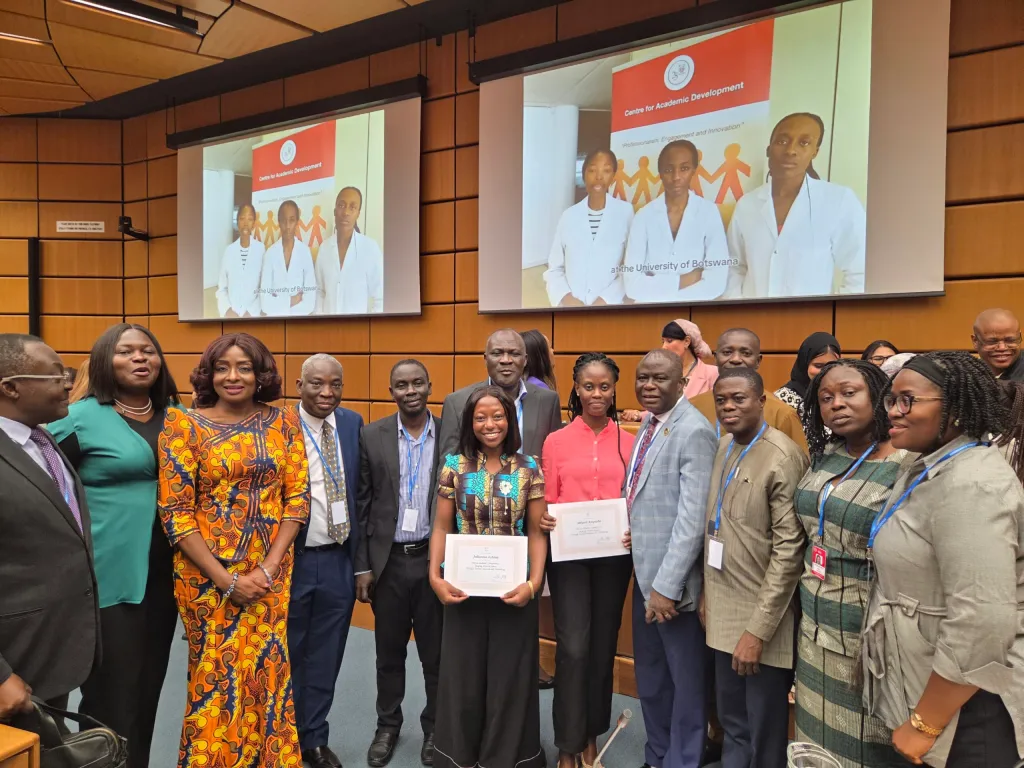

John O’Donnell, CIO and founder of Breakthrough Energy, Tobias Goldschmidt, Minister for Energy Transition, Climate Protection, Environment and Nature of the State of Schleswig-Holstein, and Dr. Thorsten Dreier, CTO of Covestro, sign a brick that will be used in the heat battery. Courtesy: Covestro

Covestro and US-based Rondo Energy have broken ground on a large-scale industrial heat battery at Covestro’s Brunsbüttel site in northern Germany, marking a significant step toward decarbonising industrial heat — one of the hardest-to-abate sources of emissions in heavy industry.

The project centres on a 100 megawatt-hour Rondo Heat Battery that stores surplus renewable electricity as heat in specially designed bricks and later converts it into high-temperature steam for continuous industrial use. Once operational by the end of 2026, the system is expected to supply around 10 per cent of the site’s steam demand, cutting carbon dioxide emissions by up to 13,000 tonnes annually.

Industrial steam generation is a major energy consumer globally and is still heavily reliant on natural gas and other fossil fuels — including across the Middle East, where petrochemicals, refining and manufacturing depend on uninterrupted heat supply. Technologies that allow renewable power to deliver round-the-clock industrial steam are therefore attracting growing attention from energy-intensive industries in the region.

Covestro’s Brunsbüttel site

The Brunsbüttel project is being supported by Breakthrough Energy Catalyst and the European Investment Bank, highlighting increasing investor interest in scalable clean heat solutions for industry.

Speaking at the groundbreaking ceremony, Tobias Goldschmidt, Schleswig-Holstein’s Minister for Energy Transition, Climate Protection, Environment and Nature, said the project demonstrated how rapid renewable energy expansion could strengthen industrial competitiveness while supporting climate goals.

“The energy transition is Schleswig-Holstein’s project of our time,” he said, adding that initiatives such as the heat battery contribute to energy sovereignty and long-term climate neutrality.

For Covestro, steam is a critical input to production and is currently generated using natural gas at the Brunsbüttel facility. The company said experience gained from the project will be used to assess whether the technology can be deployed more widely across its global operations.

“As an innovation company, we are always excited when we can further develop and test promising ideas that bring us closer to climate-neutral production,” said Dr Thorsten Dreier, Chief Technology Officer of Covestro. “The heat battery enables us to take another concrete step on our path to a sustainable future.”

The Rondo Heat Battery combines long-established materials with modern automation. Electrical energy is stored as heat using durable bricks — a concept long used in steelmaking — before driving a conventional boiler that produces emission-free steam. By charging during periods of abundant low-cost renewable electricity, the system can deliver a steady steam supply regardless of fluctuations in power generation.

Eric Trusiewicz, Chief Executive Officer of Rondo Energy, said the project addressed two of Europe’s major challenges simultaneously: managing surplus renewable power while providing reliable, affordable energy for industry.

“Together with Covestro, we are demonstrating that clean industrial heat can be highly reliable and a powerful tool for balancing the grid,” he said.

Covestro said the Brunsbüttel installation would play a key role in evaluating whether heat batteries could replace fossil-fuel-based steam generation at scale. The company aims to achieve climate neutrality for its Scope 1 and Scope 2 emissions by 2035, with Scope 3 emissions targeted for neutrality by 2050.

Rondo Energy, headquartered in California, is actively scaling deployment of heat batteries worldwide and currently operates the world’s largest industrial heat battery, also rated at 100 MWh. The company says its systems are designed to integrate seamlessly with existing industrial equipment, making them suitable for both retrofits and new-build facilities — a model increasingly relevant for energy-intensive industries in the Middle East seeking to cut emissions without disrupting operations.