Logistic Other

The logistics system that delivers the Abu Dhabi Grand Prix

The 2025 Abu Dhabi Grand Prix, as the final race of a 24‑race global season, showcased a highly complex and time‑sensitive logistics system. Operating for over ten months, the championship’s freight chain relied on precise multimodal transport—combining air, sea, and road—to move hundreds of tonnes of equipment across five continents.

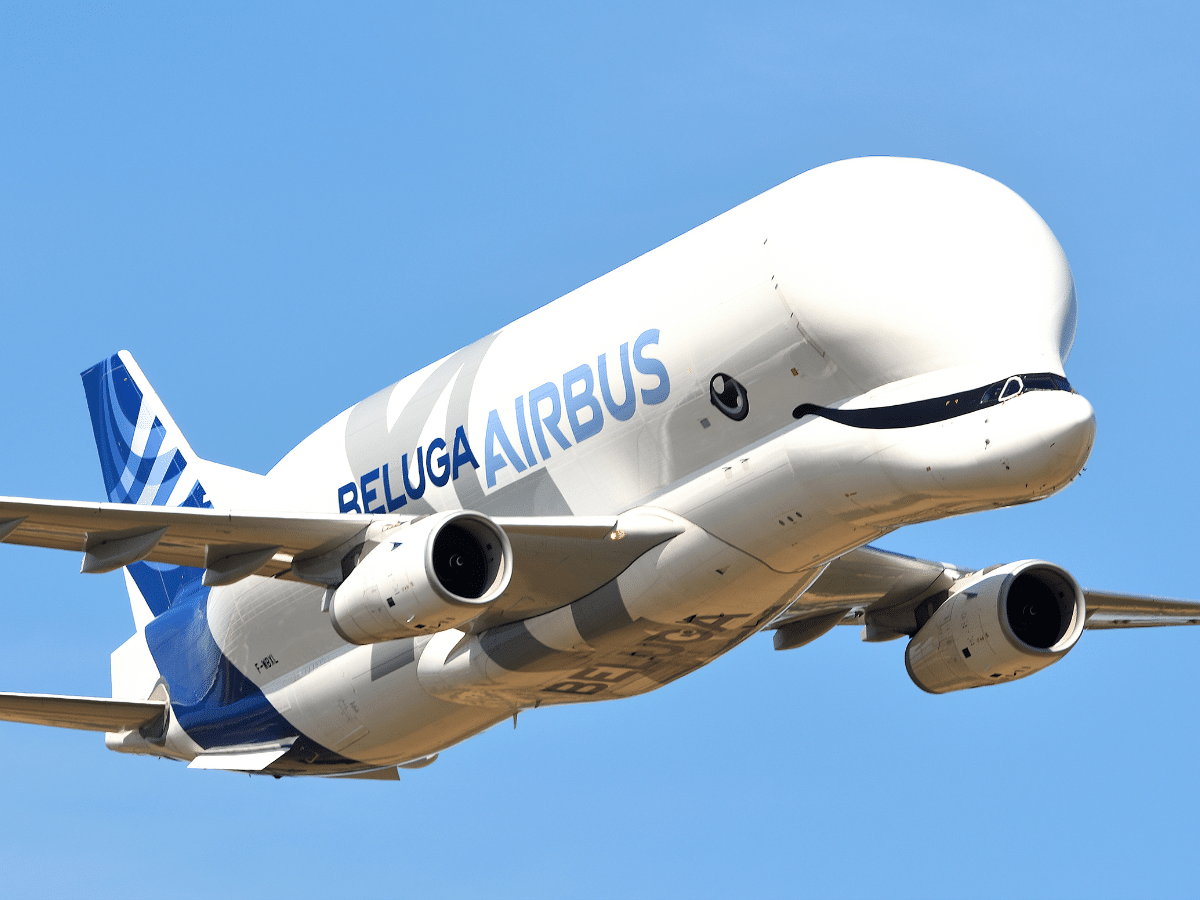

Air freight handled urgent items like chassis and electronics, with teams shipping around 35 tonnes each during overseas legs, all under extremely tight windows—especially during back‑to‑back race weekends. Sea freight moved heavier, less time‑sensitive cargo in container sets that travelled weeks ahead, reducing costs and emissions but requiring meticulous long‑range planning. Sustainability formed a key part of the strategy, with the use of sustainable aviation fuel, biofuel trucks in Europe, and optimized routing to support Formula 1’s net‑zero by 2030 goal.

Once freight arrived in Abu Dhabi, the challenge shifted to intensive local orchestration. Cargo planes were unloaded at Abu Dhabi International Airport, with equipment quickly transferred via dedicated trucks to Yas Marina Circuit. There, crews worked against the clock to assemble garages, install systems, and prepare for the race, all while managing narrow access routes and Abu Dhabi’s high temperatures. The city itself temporarily expanded its infrastructure, deploying thousands of taxis, buses, and autonomous vehicles to manage over 200,000 spectators.

The finale highlighted how global freight timelines intersect with local operational pressures. With minimal buffer after the penultimate race, success depended on flawless customs clearance, coordinated ground handling, and the host city’s ability to absorb a massive, concentrated logistical load—ultimately closing the season with a demonstration of scale, precision, and resilience.