Mining Other

River Energy proves binderless coal briquetting technology can turn waste fines into fuel

This development could help reclaim the billions of tonnes of coal waste that has accumulated in the country over decades.

Speaking at the twenty-first International Coal Preparation Conference in Sun City, on October 14, River Energy coal geologist Maseda Mphaphuli outlined how the company’s process upgraded discarded coal fines without using chemical binders or additives.

The result, she said, was a dense, low-moisture briquette with consistent burning characteristics and improved handling and transport properties.

In 2001, the then Department of Mineral Resources and Energy published a national discard inventory estimating that more than one-billion tonnes of historical discard coal had already accumulated, with a further 60-million tonnes added each year.

Based on these figures, Mphaphuli said, the total could now exceeded two-billion tonnes, including about 11-million tonnes of fine coal and slurry generated each year.

“At River Energy, we see waste differently. What we do is we reclaim and reprocess old discard dumps to produce a saleable product. We have in-house technologies that enable us to beneficiate coarse, fine and ultrafine discard coal,” she said.

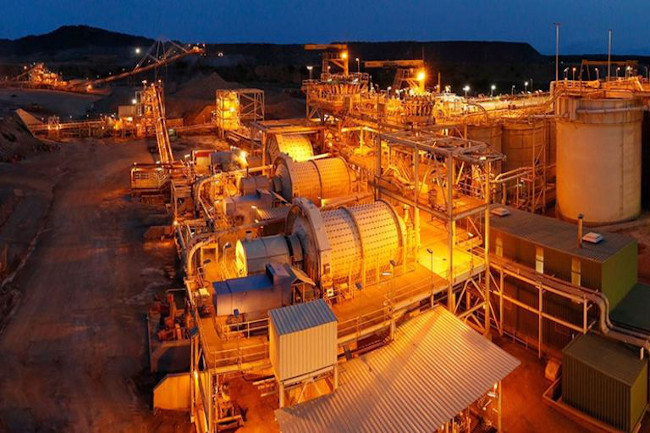

She said South African mines commonly discarded coal smaller than 200 µm – known as filter cake – owing to the technical and economic challenges of drying and handling it. River Energy’s trial unit, retrofitted to a coal handling and preparation plant, recovered this material for processing.

“In that trial unit, we managed to beneficiate the minus 200 µm material – what would typically be thrown away – and we produce a saleable product that is minus 200 µm to plus 53 µm. That product is what we then use to feed into our BCB unit,” Mphaphuli said.

The process accepts feed with up to 26% moisture content. The wet material is dehydrated in a hot gas stream before being compacted under pressure to form solid briquettes.

“What’s important about our BCBs is that we are adding no binder. When we say binderless - we add no additives. Whatever we feed in, we get out,” Mphaphuli said.

The technology was originally developed by a consortium led by Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO).

Mphaphuli said some of the coal was sent to be beneficiated at CSIRO’s 150 t/y Cessnock plant in New South Wales, Australia.

“We had positive results from the material that we had sent through to Australia,” she said, adding that there was also a one-million-tonne-a-year plant in Indonesia that also did BCB.

Following that work, River Energy built a pilot plant in Johannesburg’s Denver industrial area to replicate and confirm the CSIRO results.

“The main aim of that was to just do confirmatory testing – to confirm the results that we had received from the previous testwork. So far, we have successfully replicated the work that was done in the Cessnock plant before,” Mphaphuli said.

River Energy conducts standard characterisation on its feed and briquetted products, including petrography, moisture, particle size, calorific value and chemical composition.

Mechanical strength is tested using an in-house drop-shatter rig designed to simulate handling and transport conditions.

“We drop our briquettes onto a steel plate from about 1.8 m and then measure the level of breakage,” she said. The same method was used after exposing briquettes to outdoor weathering for seven days to assess their durability in real-world conditions.

Mphaphuli said the process achieved measurable improvements in product quality.

“We managed to improve the trade value of the coal. It’s also easier to transport due to the low moisture,” she said.

Laboratory tests showed an about 3% improvement in calorific value – from about 23 MJ/kg to 24 MJ/kg – and a reduction in moisture from 12.3% to below 3%.

Petrographic analysis of Witbank coalfield material indicated that natural clay minerals within the discard coal assist in bonding during compaction.

“Since this is the Witbank coalfield, it is rich in vitrinite and also, since it's a discard coal, rich in clay minerals – but the clay minerals allow for the natural bonding in the briquettes themselves,” she said.

Drop-shatter tests showed that the briquettes retained strength and shape after repeated handling and exposure, showing a strong resistance to breakage.

Stockpile testing, in which the briquettes were stored for four weeks, confirmed their long-term durability, showing only minor degradation.

The proportion of fine material generated through degradation remained below 15%, which meets domestic and export coal specifications.

Mphaphuli said the process had proven capable of consistently upgrading discard coal into a durable, low-moisture and market-ready fuel.

“Our briquettes have proven that we can capably briquette our feed coal and produce coal that has about 77% moisture reduction and a 3% improvement on our calorific value that is moisture-adjusted. Our briquettes are of an acceptable mechanical and weather durability in terms of handling and when stored in stockpiles,” she said.

Mphaphuli said River Energy had received interest from the mining, agricultural, chemical and household sectors. Further testing, including compressive strength assessments, was ongoing as the company explored opportunities to scale up its facility and secure offtake agreements.