Mining Other

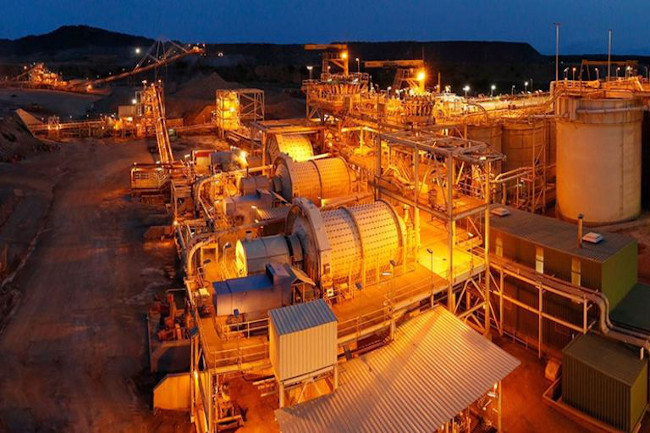

First Sandvik Hybrid Mobile Machine Launched in Southern Africa

Sandvik Rock Processing, in partnership with its southern African distributor S&R Enterprises, has launched the first Sandvik dual-powered mobile machine in the region. The unit is a tracked Sandvik QA452e triple deck sizing screen featuring Doublescreen technology.

Upon arrival, the machine was immediately dispatched to a contractor working on a major dam project in Lesotho, where it is already being used to produce construction materials.

According to PC Kruger, Business Line Manager for Crushing at Sandvik Rock Processing, the launch responds to a growing demand for electric mobile crushing and screening solutions in southern Africa. While the technology offers sustainability benefits, the primary driver in the region is the need to reduce the total cost of ownership.

“Customers in southern Africa are increasingly pursuing energy efficiency due to the significant financial benefits of reducing energy consumption, which is generally a major operational cost,” said Kruger.

Stephen Smith, MD of S&R Enterprises, highlighted the machine's hybrid “e” drive, which allows operation in either diesel or electric mode for lower operating costs and reduced emissions. Using an external electric source can lower running costs, extend drivetrain service intervals, and reduce onsite emissions and noise.

“One of the major benefits of this technology is reduced maintenance costs,” Smith stated. “The electric motor drive reduces the need for diesel engine servicing and hydraulic oil, increasing machine availability. The machine consumes up to 50% less hydraulic oil over 10,000 hours of usage.”

The standard equipment warranty has also been extended from 12 months/1,000 hours to 24 months/3,000 hours.

The QA452e features Sandvik’s patented Doublescreen technology, which uses two independent screen boxes—one as a fines extractor and the other as a grader. This design offers greater material control, adjustability, and screening efficiency, typically outperforming traditional screens by up to 30%.

“The arrival of the first Sandvik dual-powered machine marks a significant step towards a more sustainable and cost-effective future for the local mobile crushing and screening industry,” concluded Kruger.