Mining Other

Tata Chemicals Magadi to expand soda ash output to 600,000 tonnes

Tata Chemicals Magadi Limited has announced a significant and ambitious expansion plan for its soda ash mining activities at Lake Magadi, a move set to substantially increase its production capacity to 600,000 tonnes within the next five years. This strategic initiative, unveiled by the firm’s Managing Director, Swaminathan Nagarajan, is poised to boost Kenya’s exports of soda ash through the crucial port of Mombasa, solidifying the mineral’s role as a cornerstone of Kenya’s emerging mining economy.

The expansion comes at a pivotal time for Kenya’s mining sector. The latest Kenya National Bureau of Statistics (KNBS) Economic Survey for 2024 indicated a notable decrease in soda ash production by 25.2 percent in the previous year compared to 2022. This decline underscores the urgency and importance of Tata Chemicals Magadi’s current investment, as experts believe that enhancing plant operations will be critical to increasing the economic value and output of this vital commodity. Nagarajan emphasized that this ambitious plan is part of a broader strategy not only to meet the growing global demand for soda ash but also to strategically position Kenya as a key player in sustainable mineral production on the international stage.

The Heart of Production: Lake Magadi and Trona Mining

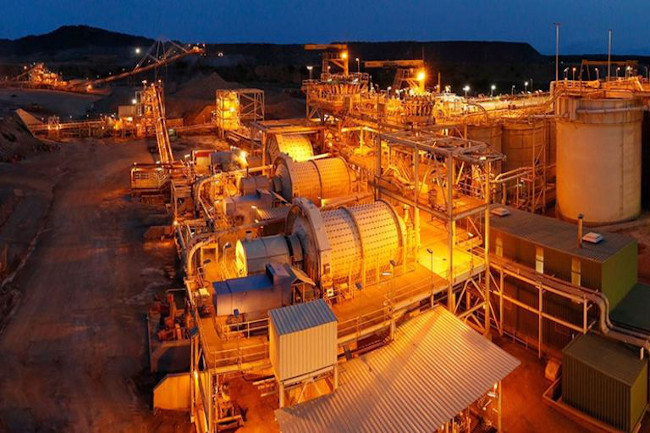

At the core of Tata Chemicals Magadi’s operations is Lake Magadi, a unique alkaline soda lake located in the Great Rift Valley of Kenya. This extraordinary geological formation is one of the few places in the world where trona (sodium sesquicarbonate) naturally crystallizes directly from the lake’s brines. The mining process at Lake Magadi is largely unique, involving the extraction of trona, which is then processed into soda ash (sodium carbonate).

The process typically involves:

- Dredging: Trona is dredged from the lakebed, where it forms dense, crystalline deposits.

- Calcination: The raw trona is then heated (calcined) to remove water and carbon dioxide, converting it into crude soda ash.

- Refining: Further purification processes are undertaken to produce high-purity soda ash suitable for industrial applications.

This natural resource gives Kenya a distinct advantage in the global soda ash market, as it allows for a more environmentally friendly and often more cost-effective production method compared to synthetic processes or mining underground trona deposits. The expansion to 600,000 tonnes within five years will likely involve significant upgrades to the dredging and processing infrastructure, potentially incorporating more efficient and larger-scale machinery to handle the increased volume of raw material and expedite its conversion into finished product. This scale-up is a complex undertaking, requiring substantial capital investment and meticulous planning to ensure operational efficiency and minimal environmental impact.

The Versatile Power of Soda Ash: Global Demand Drivers

Soda ash is an indispensable industrial chemical, often referred to as a “workhorse chemical” due to its wide array of applications across numerous sectors globally. Its versatility drives a consistent and growing demand worldwide.

The primary uses of soda ash include:

- Glass Manufacturing (approximately 50% of global demand): It is a crucial ingredient in the production of flat glass (for windows, automotive glass), container glass (bottles, jars), and specialty glass. Soda ash lowers the melting point of silica, reducing energy consumption in the glass-making process.

- Detergents and Soaps (approximately 10-15%): Soda ash acts as a builder in detergents, enhancing cleaning efficiency by softening water and preventing mineral deposits.

- Chemical Manufacturing (approximately 10-15%): It is used in the production of various chemicals, including sodium bicarbonate (baking soda), sodium silicates, and chromates.

- Pulp and Paper Industry: Used in the pulping process and for de-inking recycled paper.

- Water Treatment: Employed to adjust pH levels and remove impurities.

- Metallurgy: Used in the refining of certain metals.

The growing global population, urbanization, and industrialization, particularly in developing economies, continue to fuel the demand for glass products (construction, automotive), detergents, and other chemicals. This robust demand forms the fundamental basis for Tata Chemicals Magadi’s ambitious expansion, positioning Kenya to capitalize on these global trends.

A Green Leap Forward: Sustainability at Magadi

Beyond increasing production volume, Tata Chemicals Magadi is making significant strides in its commitment to environmental sustainability. The company recently launched a pioneering green energy project aimed at transitioning its operations from reliance on fossil fuels to cleaner solar power. This initiative involves the deployment of a 10 tons per hour electric calciner, a first of its kind in the global soda ash industry.

The electric calciner represents a major technological leap. Traditional calcination processes are highly energy-intensive and typically rely on fossil fuels, leading to substantial carbon emissions. By replacing these with an electric alternative powered by solar energy, Tata Chemicals Magadi aims to significantly reduce its carbon footprint and lower production costs. This move aligns with global efforts towards industrial decarbonization and positions the company as a leader in sustainable mineral production. The integration of renewable energy sources into heavy industrial processes is a complex engineering challenge, and the success of this project could serve as a model for other mining operations worldwide. This commitment to green energy not only enhances the company’s environmental credentials but also offers long-term operational benefits by reducing exposure to volatile fossil fuel prices.

Optimizing the Export Gateway: Mombasa Port and Regional Trade

The success of Tata Chemicals Magadi’s expansion hinges critically on efficient logistics and seamless export processes. As Nagarajan highlighted, “Over 90 percent of Tata Chemicals Magadi’s soda ash exports are processed through the facility. The company relies on seamless evacuation processes to maintain export timelines and market competitiveness.” This underscores the vital role played by the Port of Mombasa, Kenya’s principal seaport and a crucial gateway for trade in East and Central Africa.

The Port of Mombasa, managed by the Kenya Ports Authority (KPA), serves as a lifeline for landlocked countries in the region, including Uganda, Rwanda, Burundi, South Sudan, and eastern Democratic Republic of Congo. Its efficiency directly impacts the cost and speed of trade for millions across East Africa. Tata Chemicals Magadi’s engagement with KPA General Manager of Cargo Operations, Sudi Mwasinago, at the port of Mombasa, signifies a strengthening of collaboration between the mineral producer and the port authority. Dr. Mwasinago’s reaffirmation of KPA’s commitment to quick and efficient cargo handling is a positive signal for Tata Chemicals, ensuring that increased production can be smoothly translated into increased exports.

KPA has been actively investing in infrastructure to streamline the efficiency of the Port of Mombasa and the entire northern corridor. These investments include:

- Expansion of berths and container terminals: Increasing capacity to handle larger vessels and higher cargo volumes.

- Modernization of equipment: Acquiring state-of-the-art cranes and handling equipment to reduce turnaround times.

- Development of the Standard Gauge Railway (SGR): Connecting Mombasa to Nairobi and beyond, the SGR has significantly improved cargo evacuation from the port, offering a faster and more reliable alternative to road transport.

- Inland Container Depots (ICDs): Establishing and upgrading ICDs in Nairobi and Naivasha to facilitate cargo clearance closer to the final destination, reducing congestion at the port.

These infrastructure improvements are vital for supporting the ambitious export targets of companies like Tata Chemicals Magadi and for enhancing Kenya’s overall trade footprint. The meeting between KPA and the Uganda Revenue Authority (URA) at the Inland Container Depot in Nairobi further underscores the regional synergy. Captain William Ruto, KPA MD, and Mr. John R. Musinguzi, URA Commissioner General, committed to strengthening their longstanding collaboration to better serve the East African region and support business growth. This enhanced logistics synergy between Kenya and Uganda is crucial for regional economic integration and for ensuring that goods flow efficiently across borders, benefiting businesses and consumers throughout the East African Community.

Kenya’s Mining Economy: A Broader Perspective

Soda ash is a significant, but not the only, component of Kenya’s mining economy. While gold, fluorspar, and gemstones also contribute, soda ash has historically been one of the country’s most consistent mineral exports. The government of Kenya has identified mining as a key sector for economic diversification and growth, aiming to increase its contribution to the national GDP.

The expansion of Tata Chemicals Magadi aligns with Kenya’s broader vision for its mining sector, which includes:

- Attracting Foreign Direct Investment (FDI): Creating a favorable regulatory and investment climate to draw in international mining companies.

- Value Addition: Encouraging the processing of raw minerals within the country to create higher-value products, rather than simply exporting raw materials.

- Local Content Development: Promoting the participation of local businesses and communities in mining projects, including job creation and skills transfer.

- Sustainable Mining Practices: Ensuring that mining operations adhere to high environmental and social standards to minimize negative impacts and promote long-term sustainability.

The KNBS Economic Survey provides crucial data on the performance of the mining and quarrying sector. While soda ash production saw a decline in 2023, the sector as a whole holds immense potential, with significant untapped reserves of various minerals. Government policies, such as the Mining Act of 2016, aim to provide a clear legal and regulatory framework for mining activities, promoting transparency and responsible resource management. The success of Tata Chemicals Magadi’s expansion could serve as a powerful example, encouraging further investment and development in Kenya’s mining sector.

Global Soda Ash Market Dynamics: Pressure and Potential

Tata Chemicals Magadi Limited’s ambitious expansion strategies come at a time when global soda ash prices remain under pressure. This pressure is largely attributed to oversupply from China, which has significantly increased its domestic production capacity in recent years. China is not only a major consumer but also a dominant producer and exporter of soda ash, influencing global price benchmarks.

The global soda ash market is characterized by:

- Supply-Demand Balance: Any significant imbalance between supply and demand can lead to price volatility. When new production capacity comes online, especially from large players like China, it can create an oversupply, driving prices down.

- Energy Costs: Energy is a major input cost for soda ash production, especially for synthetic processes. Fluctuations in energy prices (e.g., natural gas, coal, electricity) directly impact production costs and, consequently, market prices.

- Environmental Regulations: Increasingly stringent environmental regulations in major producing countries can lead to higher compliance costs, affecting production volumes and prices.

- End-Use Demand: The health of industries that consume soda ash (e.g., glass, detergents) directly impacts overall demand and market stability.

Despite the current price pressures, the long-term outlook for global soda ash demand remains positive, driven by continued economic growth and industrialization. Tata Chemicals’ decision to expand indicates a strategic long-term view, anticipating a future where demand growth will absorb current oversupply and support higher prices. By focusing on increasing efficiency and reducing costs through initiatives like the electric calciner, Tata Chemicals Magadi aims to maintain its competitiveness even in a challenging market environment. This resilience is crucial for a company where soda ash sales volumes account for two-thirds of the giant Tata Chemicals’ overall sales.

Conclusion: A Strategic Investment for Kenya’s Future

Tata Chemicals Magadi’s ambitious expansion plan at Lake Magadi, coupled with its pioneering green energy initiative, represents a significant strategic investment for both the company and Kenya. By targeting a substantial increase in soda ash production to 600,000 tonnes within five years, the firm is not only positioning itself to meet growing global demand but also reinforcing Kenya’s role as a key player in sustainable mineral production.

The success of this expansion will rely heavily on continued operational efficiency, the seamless facilitation of exports through the Port of Mombasa, and robust regional trade collaborations. The commitment from KPA and URA to strengthen logistics synergy bodes well for this endeavor, highlighting the interconnectedness of infrastructure and trade in East Africa.

Beyond the immediate economic benefits of increased exports and foreign exchange earnings, Tata Chemicals Magadi’s investment in human capital through the STEM Africa program underscores a broader commitment to long-term sustainable development. By linking upstream investments with capacity building, the company exemplifies how private sector entities can contribute to both short-term production goals and longer-term development objectives, ensuring that Kenya’s rich mineral resources translate into tangible benefits for its people and a more diversified, resilient economy. This holistic approach is essential as Kenya navigates its path towards industrialization and sustainable growth in a dynamic global market.