Mining Other

Sovereign Metals completes its DFS at the Kasiya Rutile Graphite Project

Sovereign Metals Ltd. has announced the successful completion of a critical phase of its Definitive Feasibility Study (DFS) at the Kasiya Rutile Graphite Project in Malawi, with the conclusion of extensive geotechnical fieldwork.

The completed fieldwork is key to advancing the Tier-1 Kasiya project, as the company continues to refine its infrastructure planning and engineering designs for the development.

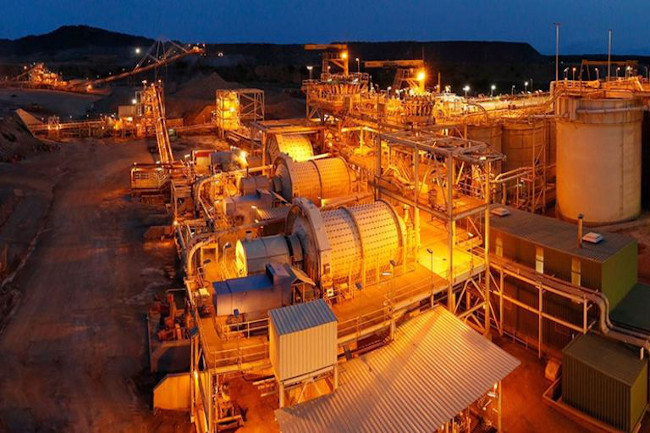

The comprehensive geotechnical investigations, conducted by ARQ Geotech (Pty) Ltd. and overseen by the Sovereign-Rio Tinto Technical Committee, were focused on key infrastructure areas integral to the project’s development, including mining operations, process plants, tailings storage facilities (TSF), and the raw water storage dam.

With more than 400 individual tests performed across the project site, the data collected will support vital engineering decisions and inform the design of foundations, earthworks, and slope stability measures.

“Completing these comprehensive infield geotechnical programs marks another significant milestone towards the completion of our DFS and another step in our systematic approach towards the development of Kasiya,” said Sovereign managing director and CEO Frank Eagar.

Geotechnical testing and findings

The field programs employed a mix of advanced testing techniques to characterise the soil and rock profiles across the project. The investigative methods included rotary core drilling, cone penetration testing, dynamic probe super heavy (DPSH) and active seismic activities.

These investigations were designed to assess the physical properties of the ground to ensure safe, efficient and cost-effective infrastructure development.

Key testing statistics from the different development areas include:

- Mining Infrastructure: More than 560 metres tested via test pits, 92 metres via dynamic cone penetration tests, and 450 metres via rotary core drilling.

- Tailings Storage Facility (TSF): 255 metres tested via test pits, 310 metres via cone penetration testing, and 13,000 metres through seismic activities.

- Raw Water Dam: 248 metres tested with auger drilling and 435 metres via rotary core drilling.

The preliminary findings from the geotechnical program indicate favourable subsurface conditions. The profiles encountered generally align with the expected regional geology, with consistent stratigraphy across infrastructure areas.

Surface soils consist of topsoil and varying materials, such as aeolian, colluvium, and alluvium. Beneath the surface, weathered soil transitions into soft rock and eventually to hard rock at greater depths, which provides a stable foundation for construction.

Optimising infrastructure and reducing costs

A key takeaway from the findings is the identification of suitable subsurface conditions for standardised foundation designs, which could reduce engineering complexity and construction costs. Notably, the ferricrete within the transported horizon was assessed as potentially reusable as engineered fill material, further enhancing the project’s cost-efficiency.

The geotechnical data will be integrated into the ongoing DFS workstreams, supporting the detailed engineering design for infrastructure placement, foundation design and construction methodologies. This will help de-risk the infrastructure planning process and ensure the project remains on track for development.

Sovereign Metals remains focused on advancing the Kasiya project, anticipating it could become a significant producer of rutile and graphite, both key materials for the growing green technologies sector. With this latest milestone completed, the company is steadily moving towards the next phases of the DFS and preparing for the eventual development of Kasiya.