Mining Other

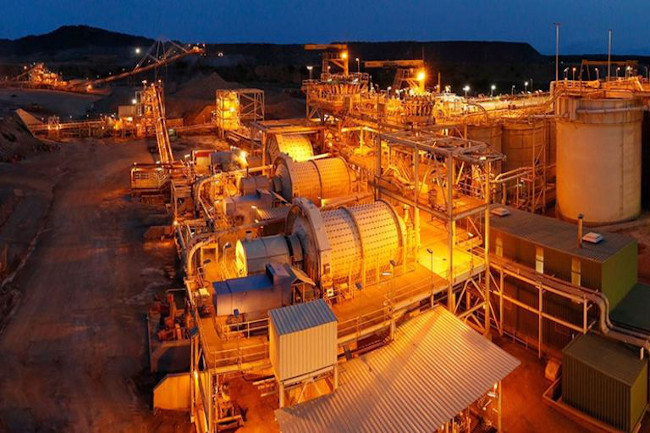

Nigeria’s $400M Rare Earth Processing Facility Transforms African Mining

Global supply chain dynamics increasingly favor nations with established processing capabilities for critical minerals over those focused solely on raw material extraction. Nigeria's development of a rare earth processing plant reflects this strategic shift, leveraging decades of experience in hydrocarbon refining to enter the complex domain of lanthanide separation and purification.

The nation's approach fundamentally diverges from traditional mining models. Rather than following the conventional sequence of exploration, mine development, and then processing, Nigeria is positioning downstream processing infrastructure as the cornerstone of its critical minerals strategy. This processing-first methodology represents a calculated bet on capturing greater value within global supply chains, where processing operations command significantly higher margins and strategic importance than mere extraction.

Nigeria's $400 million facility in Nasarawa State inverts the traditional development timeline, aiming for operational capacity in 3-5 years instead of the 8-12 years typical for integrated mine-to-mill projects. This standalone processing plant is designed to source feedstock from multiple suppliers, reducing geological risk and attracting exploration investment by providing assured offtake. The strategy capitalizes on Nigeria's existing industrial foundations, particularly expertise in large-scale chemical separation, hazardous material handling, and complex logistics honed in the petroleum sector, as demonstrated by projects like the Dangote Refinery.

The facility will process monazite sands, focusing on light rare earths. A key economic challenge is the revenue concentration: high-value elements like neodymium and praseodymium (crucial for magnets) constitute only 10-16% of the output but generate 45-60% of potential revenue, while more abundant elements like cerium and lanthanum have lower market values. Success will therefore depend on maximizing recovery of premium elements and developing markets for co-products.