Mining Other

Local branch improves pumps, parts availability

“This expansion launched the capability to successfully offer our clients, in Zambia, some much needed local support and tailored products.”

Goodwin Submersible Pumps is continuously aiming to develop its installed base in Zambia, with Gomes noting that this endeavour entails the introduction of newer pump designs and upgrades to that market.

Prior to establishing the branch, Goodwin conducted business with Zambian mining companies from its base in South Africa; however, logistical challenges associated with cross-border shipping made establishing a local presence necessary to ensure it could continue to deliver the high service standards clients expected, says Gomes.

“As an original-equipment manufacturer (OEM) of the Goodwin range of submersible slurry pumps in Africa, we had to ensure that our reputation of supplying high-quality, reliable and cost-effective slurry pumping solutions was replicated in Zambia.”

The Zambian branch of Goodwin sells new pumps and spare parts, maintains a fully stocked warehouse of spares, and provides pump repair, maintenance and aftermarket services.

Going forward, the company’s focus will be on Zambian service and support.

“Our Zambian customers, most of them being copper-producing mines, benefit from the quick turnaround times for pump repairs, the availability of spares in-country and our technical expertise when supplying Goodwin submersible slurry pumps to some of their most challenging applications.”

Diverse Range

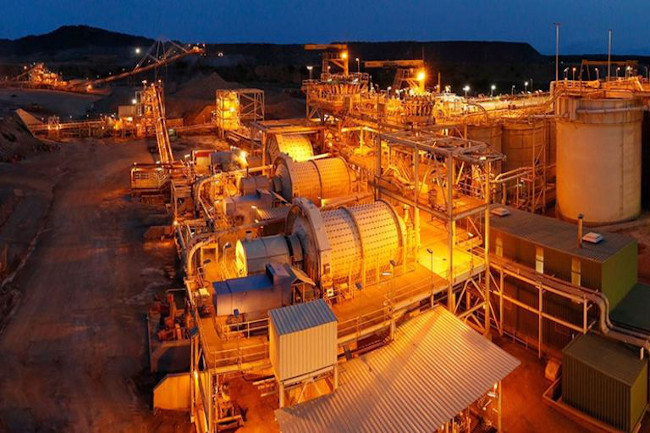

The various ranges of Goodwin submersible pumps on offer are well suited to the harsh mining environment in Zambia, and in copper mines in general, states Gomes.

Goodwin’s flagship 100ANZE can handle dense slurries of up to 2.8 kg/ℓ, while the bigger 200ANZE pump can deliver up to 800 m3/h.

The company’s submersible slurry pumps are widely used in mine tailings recovery and reprocessing, minerals processing plant sumps, spillage clean-up applications, power plant ash dams and tank de-silting.

Goodwin has also designed 100 mm and 150 mm discharge high-head dewatering submersible pumps, available with 90 kW or 150 kW motors respectively, which are “ideal” for high-wall dewatering applications, as they can deliver water to a discharge head of 180 m.

The company also offers the 100SDSS stainless steel submersible pump, designed for unique applications that contain slurry and acids.

Where the industry standard stainless steel pumps are not suited to handle slurries, the 100SDSS is engineered to withstand the “toughest conditions”, whether corrosive or abrasive.

“This pump also offers exceptional resistance to wear, rust and damage,” Gomes adds.

Meanwhile, Goodwin has partnered with various logistics companies that service different regions in Africa to transport products to clients by air, sea or road.

Gomes acknowledges that even with well-versed logistics companies on board, the most prominent challenge faced when supplying clients in Zambia is timeframes, as crossborder issues arise frequently – an issue exacerbated by degrading infrastructure and remote site locations.

“Having a facility and holding stock in- country goes a long way towards mitigating those challenges. Our well trained and capable staff have assisted our customers with their Goodwin pump maintenance on site and at our workshop facility in Kitwe,” concludes Gomes.